| Previous | Next |

Point Cloud Processing

Illinois Institute of Technology

Overview

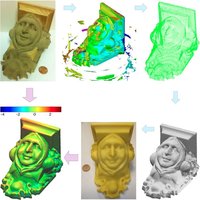

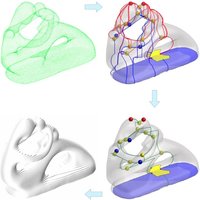

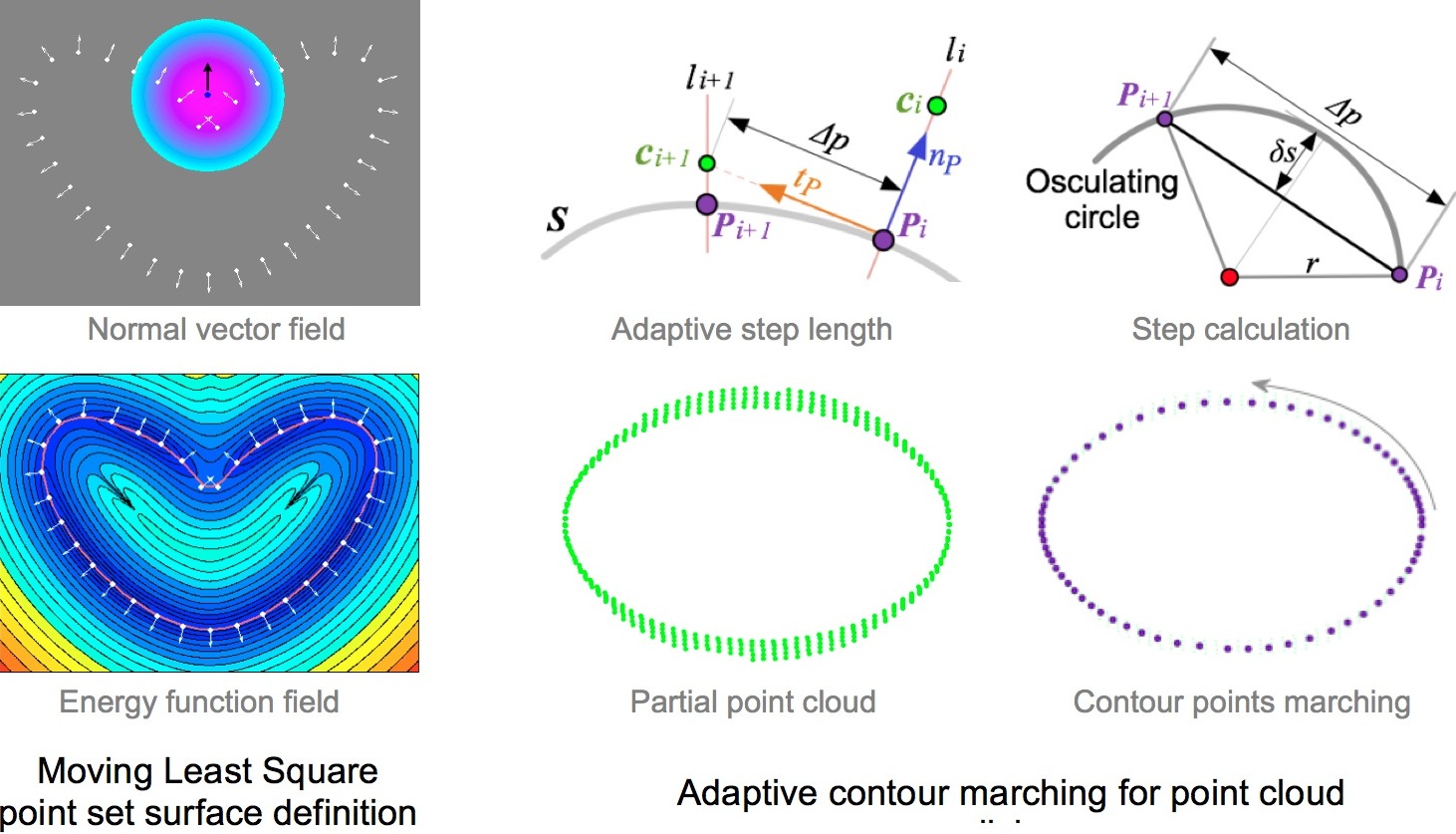

As 3D scanning devices and technologies become more and more popular, algorithms are widely needed for the geometric processing on scan data in product design/analysis/manufacturing. Traditional approach typically involves an intermediate conversion to triangle mesh. Our proposed algorithm utilizes the promising Moving Least Square definition for point-set surfaces representation; it works directly on point data and circumvents the mesh conversion step, significantly improving the efficiency of the entire product development life cycle.

We have focused on the additive manufacturing (3D printing) capabilities of proposed technique, and developed a smart slicing algorithm with both geometric and topological awareness. The algorithm has been tested on digital models and we have also demonstrated its ability in transmitting 3D geometric manufacturing data in a tele-fabrication practice.

We are very thankful to the National Science Foundation for the following grants:

- Award #0529165 SST/GOALI/Collaborative Research: Multi-Sensor Planning, Integration, and Analysis for Dimensional Quality Control of Complex Manufacturing Processes

- Award #0900597 Direct Digital Design and Manufacturing (D3M) from Massive-Point-Cloud Data

- Award #1030347 Direct Measurement from Scan Data with Adaptive Moving Least-Squares Surfaces under Controlled Spatial Dependency

Publications

Pinghai Yang, Kang Li, and Xiaoping Qian